NOWA RUDA PROJECT

In July 2013, Balamara was awarded the exclusive rights to this exciting coking coal project in south-western Poland. Balamara’s 100% owned Polish subsidiary company – Coal Holding- has been granted the Exploration Concession for the Nowa Ruda coking coal deposit by the Government of Poland, providing an excellent opportunity for the Company to reposition itself as a significant mid-tier player in the international coal industry.

About NOWA RUDA

In July 2013 Balamara was awarded the exclusive rights to the substantial Nowa Ruda coking coal project in south-western Poland, which comprises a series of previously undeveloped zones, with historical production over several decades of around 1 Mtpa of high-quality coking coal. Mr. Andrzej Zibrow, an experienced Polish mining executive is Chief Executive of Coal Holding, with responsibility for managing all corporate, technical and operational aspects of delivering the Nowa Ruda Coking Coal Project.

Balamara’s preliminary drilling program was undertaken and an updated JORC Resource report delivered in June 2015. At present a Pre-Feasibility Study is also being completed.

History of mining in Nowa Ruda

Coal mining has been conducted in the Lower Silesian Basin since the late XV century, making this one of the oldest coal producing regions in Poland, typically averaging 0.25 – 0.5 Mt coking coal per annum prior to 1945. Post 1945, production increased significantly and peaked between 1980-1995 at an average of 1.0 – 1.2 Mtpa.

For two decades until its closure in 1995, the nearby historic mine produced circa 1 Mtpa of coking coal, over 90% of which was sold to local coke plants, with the majority going to the Walbrzych plant, which is sited only 40 kms. away and linked to Nowa Ruda by rail. This gives Balamara further confidence that the end-product will be acceptable to local coke plant requirements.

Project Pathway

Latest update: August 2020

Concession Area (sqr. km)

Boreholes drilled within Balamara's Drill Campaign

Approx. combined length of drilled boreholes in mts

Historical Boreholes applied in Geological Report

Total JORC Resource (Mt)

Exploration Concession Area

Nowa Ruda Announcements:

04/06/2018

Nowa Ruda Positive Environmental Impact Decision announcement

09/06/2015

Nowa Ruda Updated JORC Resource

13/04/2015

Completion of Nowa Ruda Drilling

10/03/2015

Nowa Ruda Drilling Update

Governmental Decisions:

Minister of Environment Exploration Concession Decision No 8/2013/p of 18.07.2013

Exploration concession decision amendment of Minister of Environent of 12/01/2016, implementing previous decision No 8/2013/p

NOWA RUDA Geological Report Approval Decision

LECH Field Deposit Development Plan Approval decision issued by District Mine Office in Wrocław of 30/07/2015

Deposit Description

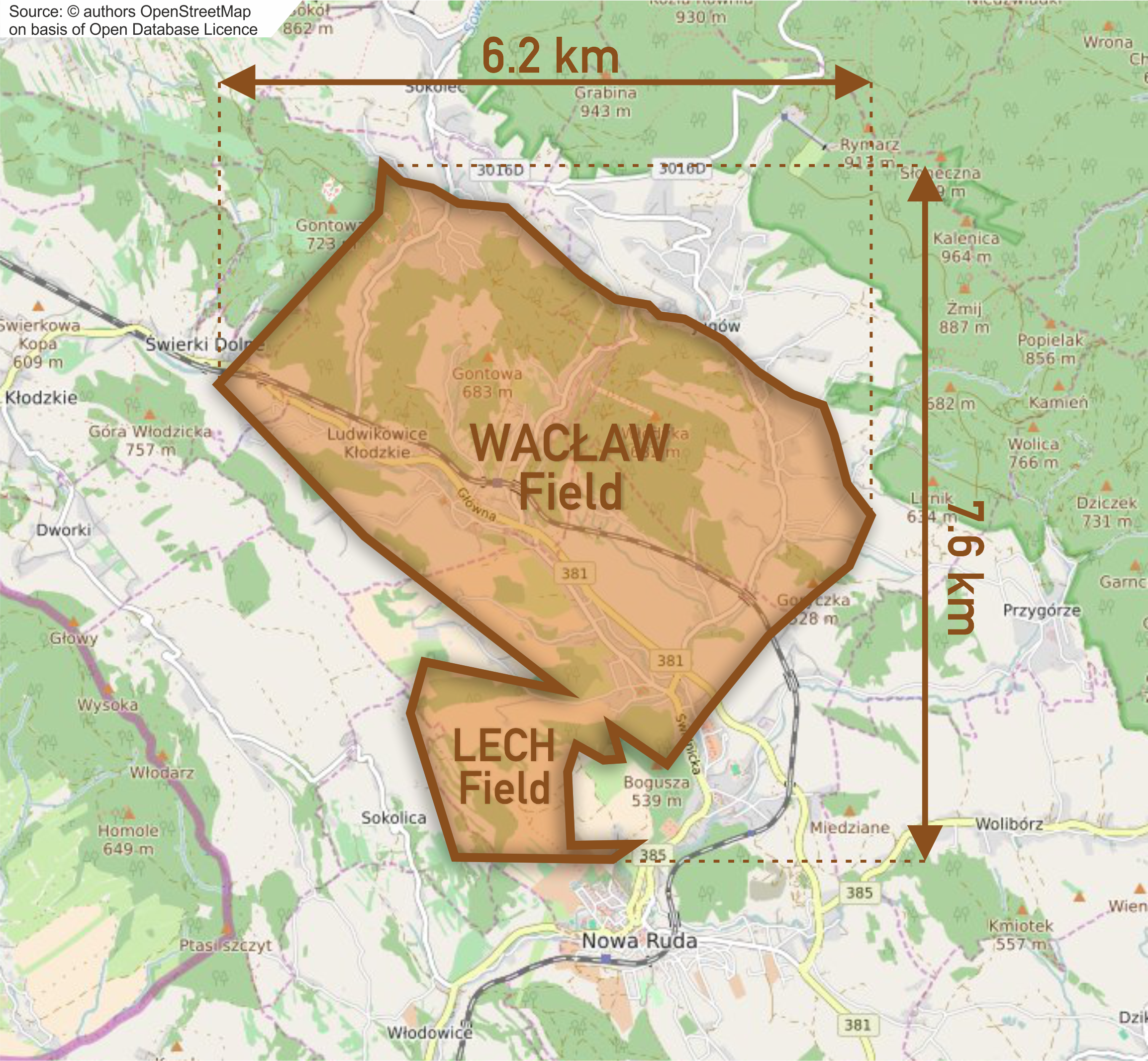

Nowa Ruda is one of the two coking coal assets owned by Balamara Resources Ltd in Poland. It is located in the Central Sudeten range within the Lower Silesian Coal Basin, close to the Czech Republic border. It consists of a single lease area covering two large, adjacent coal deposits – known as WACŁAW on the north side and LECH on the south side. The two fields are considered as separate deposits, split by a major fault with an NW – SE axis. The coal seams within the concession area range up to 2.75m at WACŁAW Field and up to as much as 7.0m at LECH. The project covers a surface land area of approximately 26 km2 and includes extensive key infrastructure such as roads, rail, power and water in the area.

Exploration Works

The Polish Geological Report, prepared by Balamara on the basis of its own Preliminary Drill Campaign as well as purchased historical exploration data, was approved for both the WACŁAW and LECH Fields by the Ministry of Environment in December 2014. The evaluation decision of the Mineral Resources Committee (K.Z.K.) states that the balanced-class Resource is equal to 83.886 Mt for WACŁAW and 32.097 Mt for LECH (totalling 115.983 Mt) within Polish resource reporting standards. Cautious JORC-coherent estimation has also been applied, showing a total Resource of 86.4 Mt. This Resource Estimation was prepared using existing data from 11 historical drill holes and substantial associated data. Balamara is also successfully carrying out a drill campaign as a part of its exploration works. The total length of boreholes drilled by Balamara is over 7.5 kilometres. Every drill-hole has been made in compliance with all JORC standards, and obtaining 100% core yields. The full length of each borehole has been fully logged by the experienced geophysics company – “Geofizyka Kraków”. Hydrogeological works have also been applied, including pumping and studying all of the aquifers present within the overburden. Cores have been sampled and forwarded to certified laboratories within Poland to be tested according to internationally recognized standards. The scope of laboratory works included geotechnics, geomechanics, hydrogeology as well as coal quality testing.

The experienced Mining consulting firm HDR were commissioned to perform an evaluation of the Nowa Ruda project using a combination of 11 historical drill holes, 7 new holes completed in 2015 and purchased historical data. The Pre-Feasibility Study was subsequently completed during 2015, revealing the high quality and economic viability of the Nowa Ruda deposit. The coal quality data is shown in the Table below.

| Resource Calss. |

Tonnes (Mt) |

Raw moisture (adb), % |

Raw volatiles (adb), % |

Raw sulphur (adb), % |

Raw ash (adb), % |

Raw GCV (kcal/kg) |

|---|---|---|---|---|---|---|

| WACŁAW Measured Indicated |

9.9 | 1.06 | 18.94 | 1.32 | 26.11 | 25.13 |

| WACŁAW Inferred |

45 | 1.03 | 18.86 | 1.14 | 29.17 | 24.23 |

| LECH Measured Indicated |

20.5 | 0.85 | 18.25 | 0.73 | 24.63 | 25.03 |

| LECH Inferred |

11 | 0.89 | 18.12 | 0.81 | 27.02 | 26.64 |

| TOTAL | 86.4 | |||||

Mining Method

Based on a combination of historical exploration data, recent drill campaigns, core sampling and laboratory analyses, our submitted Polish Geological Report and state-of-the-art design and engineering works, Balamara successfully completed, submitted and was awarded approval for its Deposit Development Plan by the District Mine Bureau (O.U.G.) in Wrocław in June 2015. Receipt of this document was a significant milestone on the way to making our Mining Concession Application. A Deposit Development Plan taking into consideration the high variations of seam dips across the deposit (from completely flat zones to highly dipping areas) was compiled on the assumption of employing a mixed mining method, i.e. to apply both Room-and-Pillar and Longwall systems.

The Room-and-Pillar method is based on a network of perpendicular, crossing workings, with pillars of coal mass in between, providing better roof support and giving ability to control strata subsidence when mining is in progress. Room-and-Pillar mining will suit the local conditions at Nowa Ruda, especially in the shallow-angle dipping zones, which are mostly where the best quality coking coal can be found across the deposit area. It should be noted that Room-and-Pillar mining provides greater safety for the miners in terms of gas-burst hazards. Gas saturated within the seams can be more easily drained and ventilated, due to the dense network of workings, and the greater amount of drained surface than in longwall mining. Room-and-Pillar is a mining method providing high selectivity and flexibility of mine geometry, being successfully applied in mines worldwide, particularly where complex tectonics make longwall mining challenging and uneconomical. Room-and-Pillar methods employ self-propelled machinery, which gives the advantage of inexpensive and rapid transportation, without the necessity of disassembling the vehicles before deploying them underground. Advanced geotechnical analyses have been conducted in order to develop the safest and most efficient mine geometry (including pillar sizing, workings offset, etc.), tailored to the local conditions at Nowa Ruda. The mining itself is designed to be carried out using state-of-the-art machinery, including highly efficient continuous miners, shuttle cars and conveyers as basic equipment. In order to provide safety for the miners, a set of bolter vehicles will also be applied, to secure roofs and sidewalls with bolted support, reinforced with steel plates and meshes.